What Happens When a Bullet Hits Polymer Armor?

When a bullet hits polymer armor, it penetrates into the outermost layers of the armor. As friction becomes an increasing force, the projectile will typically fragment or yaw, and its ability to penetrate further into the armor's material is halted.

Below we will dive into more depth into what happens to polymer armor when it is hit by a bullet.

What is Polymer Armor?

Polymer armor is one of the newest armor material types on the market. Not just any polymer will work in this capacity, but a specific blend of flexible fibers and polymer sheets pressed together to make a solid plate is what's required to stop a round. Most ballistic rated polymer is composed of Ultra-High Molecular-Weight Polymer, or UHMWPE (PE for short).

The Pros of Polymer Armor

UHMWPE is lightweight, in fact, it's the lightest multi-hit rifle-rated material on the market and is lighter than a single steel or ceramic armor plate. This allows you to do more physical activities in your kit with far less fatigue - extending your fighting capabilities.

In addition to being lightweight, UHMWPE is buoyant, meaning the plates will not act as an anchor should you end up in the water during the course of your armor usage.

What Happens When Polymer is Shot?

Polymer armor, due to its composition and limitations, reacts quite differently than both steel and ceramic armor types when it's shot.

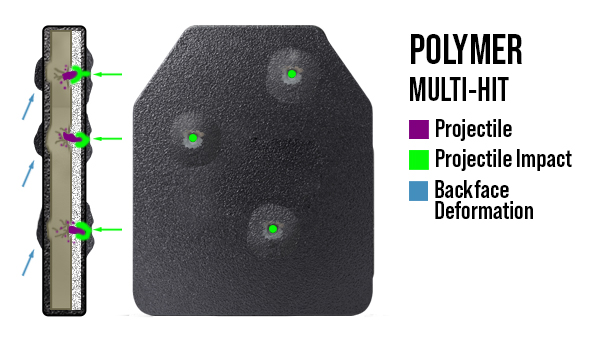

As the projectile starts to penetrate into the layers, two things will happen:

- The projectile will start to deform and yaw (or turn on its side): This has to do with the physical resistance the polymer is providing to the projectile and the projectile's ogive (roundly tapered end of a two/three-dimensional object) shape. It's not uncommon for high-velocity rounds like 5.56 to still fragment apart within the first few layers of UHMWPE. Once the projectile begins to yaw or fragment, it becomes embedded in the remaining layers of the fiber-reinforced polymer as it penetrates.

- The polymer layers stop the rounds and the friction caused heats up the UHMWPE into a more pliable state: Due to round density and mass displacement, once the PE is heated up, it will deform to become thicker in areas where rounds were stopped. This effectively causes “backface deformation” or BFD bulges. It's not uncommon for really hot projectiles or bullet fragments to also melt the polymer surrounding it once they come to rest - gluing them in place.

The Cons of Polymer Armor

There are four primary considerations that need to be made when choosing UHMWPE armor:

- Deformation: Part of UHMWPE's ability to stop a round requires that it deforms. This deforming of the plate translates to an increase in energy transferred to the wearer. That means that although taking a round in any capacity can be a painful experience, PE will deform more than both steel and ceramic strike faces.

- Cost: Since this is a newer material and requires a large overhead for production, the cost on PE plates can often be some of the highest on the market. The term “you get what you pay for” is certainly true here.

- Shelf Life: In addition to being on the higher end of the cost spectrum, UHMWPE only has a shelf life of 5 years. Since PE breaks down with UV and sweat exposure, it's important that you take note of your armor's expiration date and replace it as close to that date as possible.

- Steel Core Ammo: If cost, shelf-life, and deformation are all small hurdles and you simply want the best, the last thing to know is how UHMWPE reacts when shot with steel core or armor-piercing ammunition. We discussed how UHMWPE works when hit above with an emphasis on yawing or fragmenting the round. In order to do so, the projectile material needs to be softer in composition. This means projectiles made of copper, brass, and lead are easy to deform and stop even at higher velocities, while steel core ammunition will typically maintain its hardness and effectively pass through the plate. This means even though UHMWPE can stop rifle rounds like 308 and 5.56, if there is a mild steel core in the projectile, it will possibly pass through. Even putting a soft armor 3A panel, like our S2 behind the plate, is no guarantee to stop rounds like the 5.56 M855 “green tip”.

Conclusion

Polymer armor is one of the most effective armor types out there in terms of weight mitigation. Consider that you will spend 99.999% of your time in your armor not getting shot and the weight savings mean the physical restraint of using ceramic or steel plates for long periods of time is all but non-existent. This can lead to you wearing armor longer, more effectively protecting you when other armor types would have long since caused fight-hindering fatigue. If operating in an environment where steel projectile-type ammo is prevalent it may be good to look into hybrid armor types like our A3 plate that combines a lightweight steel strike face in front of UHMWPE layers to stop rounds like the M855 green tip.

For those who are more likely to see water-based environments in armor, or who need to mitigate the most weight possible while maximizing protection, a polyethylene plate, like our P2, is a solid pick.