What Happens When a Bullet Hits Alloy (Steel) Armor?

When a bullet hits steel core armor, it will fragment and redirect outward conically. Depending on the plate’s external surface resistance coating it will either be arrested in place or become an outward hazard.

Below we will dive into more depth into what happens to alloy (steel) armor when it is hit by a bullet.

What is Alloy Armor?

Alloy armor is essentially steel, which is arguably the simplest and most effective type of armor on the market. Manufacturing steel involves cutting a high-carbon heat-tempered steel plate in the shape of an armor insert. Most steel armor is made with a range of AR500 - AR650 steel. It is used in vast protection applications ranging from vehicle armor, to military checkpoint protection, and individual armor usage.

Pros of Steel Alloy Armor

In its purest form, a simple piece of steel can stop or mitigate a ballistic threat. Steel stops projectiles by presenting a surface that is harder and with a greater density than the projectile's mass and velocity that hits it. This armor is able to take multiple hits with no structural demise due to its flexibility, and if surface pitting or penetration does not occur when struck - will remain unphased round after round

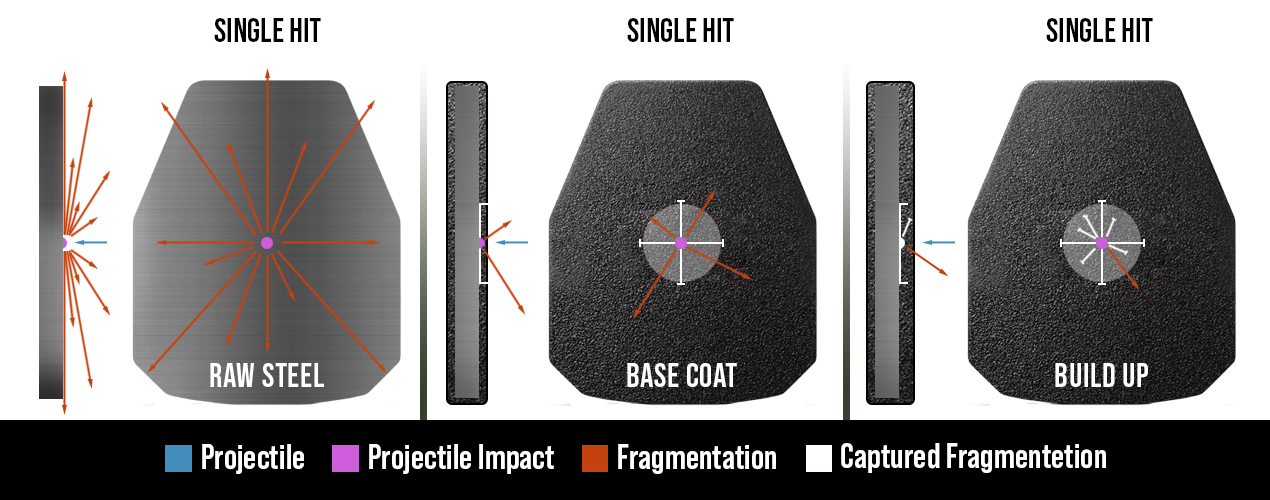

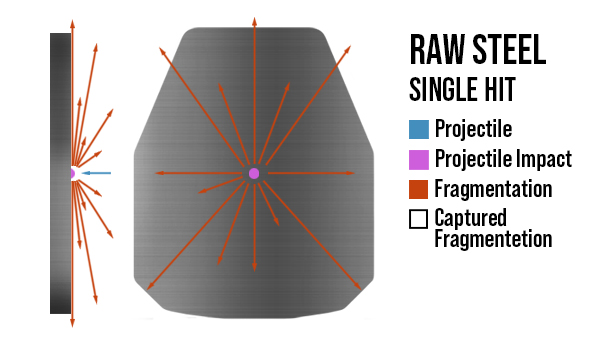

What Happens When Steel is Shot?

Since steel body armor is a combination of surface hardness and material flex, the energy created by the projectile will always flow toward the path of least resistance. In the case of steel armor, the path of least resistance of the round is almost always “back the way it came”. This means the energy of a round hitting steel will almost always result in the projectile imploding on itself and fragmenting in an outward conical shape, typically relevant to the direction it hits the plate.

What happens when raw alloy (steel) armor is hit by a bullet

Cons of Steel Alloy Armor

Fragmentation or the outward spray of small metal pieces that were formerly the ballistic projectile is most often the only hazard of using steel armor. Fragmentation is a real issue and needs to be strongly vetted when making an armor purchase. For some, the risk of fragmentation is little to none based on their limited forecast of armor usage. For others, who are seriously planning to overcome an armed encounter or potentially more than one, we strongly suggest taking steps to mitigate fragmentation.

What Happens When a Plate WITHOUT a Protective Coating is Shot?

Since there is no surface layer build-up coating to resist the fragmentation, there is essentially nothing preventing its escape. Once a projectile hits the plate and penetrates the base coat, the fracturing of the round will effectively produce a conical-shaped outward implosion of fragmentation (this usually travels between 5 to 15 degrees off the body). This means fragmentation is unlikely to travel at a 90-degree angle (as most might assume) and depending on where parts of your body are like your face and arms, this may be enough to prevent serious fragmentation injury. In situations where you are sitting down or your arms are extended holding a weapon elongated, you are likely to see fragmentation injury.

What Happens When a Plate WITH a Protective Coating is Shot?

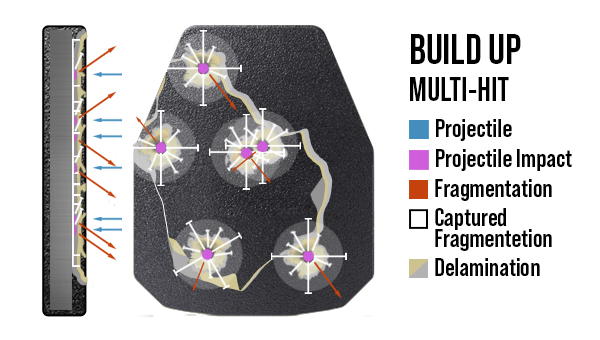

Steel armor that has a dense material build-up on the strike face is one of the most common ways to address fragmentation concerns. While some manufacturers use a type of truck bed liner, here at Armored Republic, we use a proprietary polyurea material that was designed from the ground up to stop fragmentation. This material is called FragLock. This coating is able to retain its surface strength after a bullet penetrates its outer layer and is dense enough over the strike face to prevent most if not all of the bullet fragmentation from leaving the surface.

What happens when build-up alloy (steel) armor is hit by a bullet

Are There Any Limitations to FragLock?

Yes. The application of Armored Republic’s FragLock build-up coat is meticulous. There are multiple variables that go into how FragLock functions. It involves a careful balance of thickness, material flex, surface hardness, and most importantly adhesive to the steel core armor. Since the material has to be on the steel core for it to function, the biggest limitation is delamination or separation from the plate. Once FragLock begins to delaminate from the steel, fragmentation is allowed for a larger void area between the plate and the remaining adhered coating. With each consecutive hit, this void will spread until a corner or edge is completely separated from the plate. After edge separation has taken place, seepage and redirection of fragmentation will likely occur in that direction.

What is the Cause of Surface Delamination of FragLock Build-Up Coating?

Delamination refers to the mechanical separation of the FragLock coating and ballistic steel core. The sole source of this delamination is from rounds being stopped. The more rounds a plate stops, the more delamination you will see.

When understanding the process of delamination, there are a few key talking points:

- Rounds on the plate will be the sole contributing factor to the delamination of the coating: Rounds that group in the same general area will cause accelerated delamination since the previous round in that area had already delaminated portions of the coating.

- A heavier round will cause more delamination than a lighter projectile at similar velocities: Generally speaking, rounds that are lighter in weight but faster (like 5.56) will see less delamination, while rounds like 308 will typically delaminate more due to the mass of M80 (147GR) being almost 3x times the mass of 5.56 (55GR). In this example, the velocity/mass of 5.56, 55GR projectile at 3,100 FPS will not delaminate more coating than a 7.62x51, 147GR projectile at 2,700 FPS. Although 5.56 may have a harder impact on the steel due to velocity, its mass is relevant here since that is what the fragmentation coating is having to contain.

- A faster round of similar weight to a slower round will cause faster delamination: Along with the relevant mass topic noted in #2 above, velocity is the next metric to understand delamination. You can have two rounds that are identical in weight but due to a difference in velocity, the faster round will delaminate more material. A prime example of this is looking at a 147 GR 9mm versus the 7.62x51mm M80 Ball. Both are the same weight as far as the projectile goes, but the 9mm is only about 1,000 FPS while the .308 is closer to 2,800 FPS. Likewise, you will see far more delamination here with the M80 strike due to the increased velocity of the projectile.

- The closer the shots are to the edge of the plate, the quicker you will see fragmentation leakage: This has to do with the mass of the smashed-out projectile spreading out along the protective surface of the plate. On an edge shot, the steel strike face will “run out” of material at the edge of the plate, and at that point, since there is no physical material to redirect the frag, it will simply exit the edge of the plate. This means edge shots are more likely to produce frag leakage quicker than center mass hits will.

Are There Other Steps I Can Take to Prevent Fragmentation with Steel Armor Usage?

- Add a Fragmentation Containment Sleeve: you can add further protection with a Fragmentation Containment Sleeve - this one in particular is made of an aramid material located at the top half of the bag to encompass the area of the plate you are most likely to see fragmentation at. Likewise, on a base coat plate, this will add upper quadrant frag protection, ensuring fragmentation stays out of areas like your neck, chin, and shoulders. This fragmentation protection can also be used on build-up coat plates as an extra layer of protection and prevention if you take enough rounds to delaminate the build-up coating.

- Add a Soft Armor Panel: you can address fragmentation for a base coat steel plate by placing a Soft Armor Panel in front of the plate to help mitigate fragmentation. As fragmentation is redirected off the surface of the strike face, it gets reinjected into the soft armor panel where it becomes immobilized. This method is not as effective for build-up coat plates once they become delaminated.

Conclusion

Steel armor is one of the most practical and economical armor types out there. Using modern redundant solutions to address fragmentation is only the next evolution of keeping you in the fight.